2025 Hot Water Boiler Recommendation

date: 2025-05-15

Page preview:

Summary

FANGKUAI Boiler Co., Ltd. offers a comprehensive series of commercial hot‑water boilers—gas‑fired vertical, water‑tube, integrated, split, vacuum, electric, condensing and even coal/biomass variants—that span outputs from under 100 kW to over 70 MW. They combine high thermal efficiency (up to 97 %), low emissions, space‑saving designs and flexible installation options.

Gas/oil‑fired models suit everything from small restaurants to large shopping malls; vacuum units excel where safety and low heat loss are critical; electric boilers deliver zero on‑site emissions; and condensing H7 units push efficiency to the industry’s top tier. Below we profile each product, highlighting its key specs, strengths, ideal scenarios.

Company Background

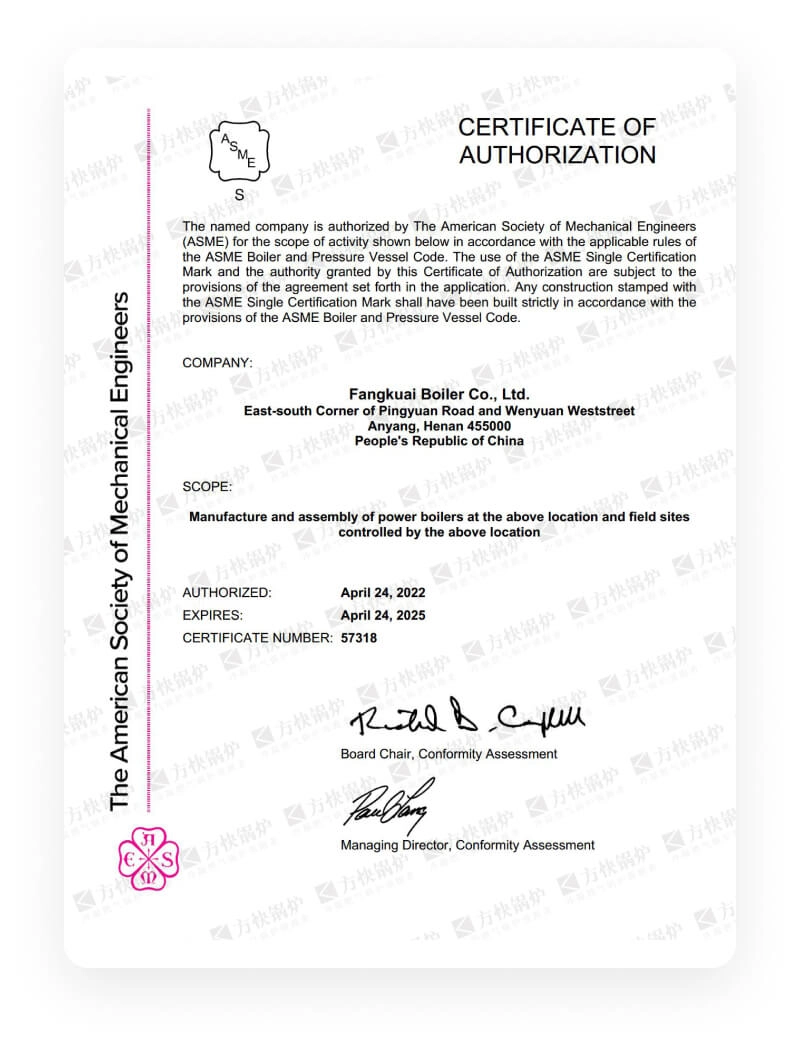

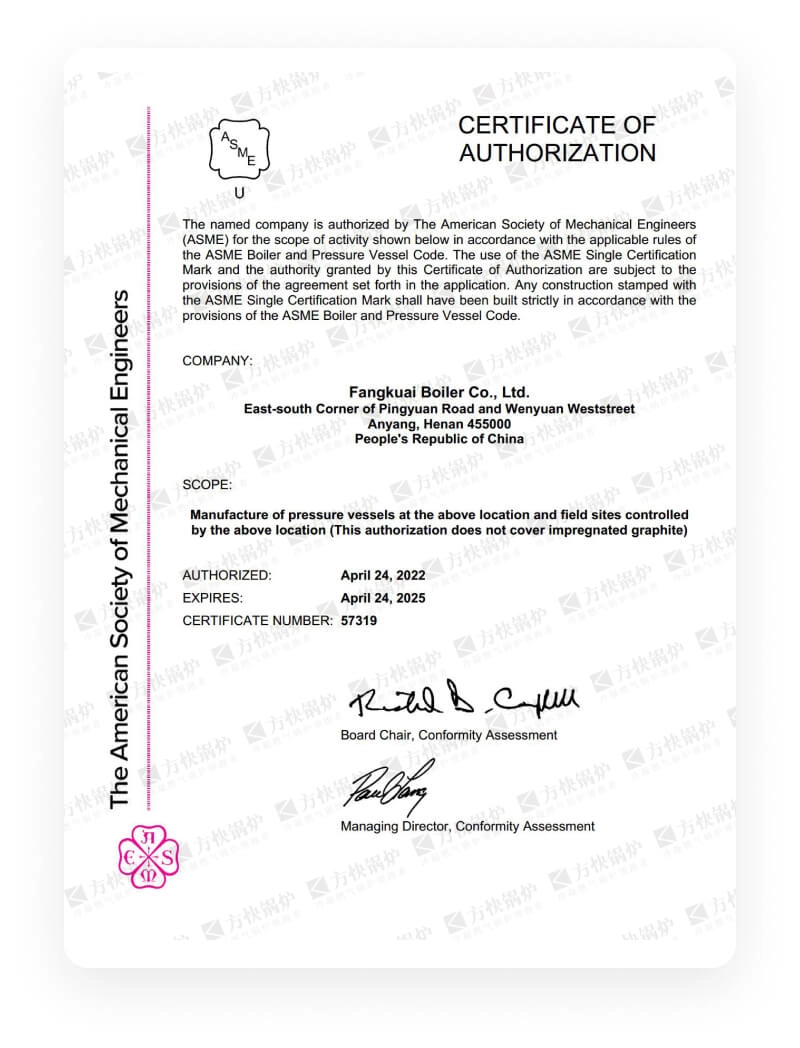

Zhengzhou FANGKUAI Boiler Sales Co., Ltd., founded in 1998, is a licensed Level‑A boiler manufacturer with two production plants, an R&D center and a full working‑condition laboratory—totaling 120,000 m² of manufacturing space. Their annual output exceeds 20,000 tons of steam and hot‑water capacity, with over 107 R&D patents, serving hotels, schools, malls and industrial clients worldwide.

FANGKUAI boilers consistently achieve at least 15 % higher thermal efficiency than ordinary boilers, thanks to advanced heat‑exchange designs and strict quality control—helping clients cut fuel costs and meet tightening environmental regulations.

Product Line Overview

FANGKUAI’s hot‑water boiler portfolio includes (1) Gas‑/Oil‑Fired Vertical and Water‑Tube Boilers, (2) Integrated & Split Hot‑Water Boilers, (3) Commercial Gas Heating Boilers, (4) Vacuum Hot‑Water Boilers (T6 & T7), (5) Electric Hot‑Water Boilers, (6) Condensing Atmospheric Boilers (H7 Series), and (7) Coal‑ & Biomass‑Fired Boilers.

Each category targets different capacities, installation constraints and fuel preferences, ensuring a solution for almost any commercial heating need.

Model Details

-

Output & Pressure: 0.35–0.7 MW; 0.1 MPa

-

Fuel: Natural gas

-

Thermal Efficiency: ≥96 %

-

Advantages:

-

Compact footprint (ideal for mechanical rooms with limited floor space)

-

Simple, cost‑effective installation and maintenance

-

Ideal For: Small hotels, restaurants, office buildings

-

Recommendation: ★★★★★ (4.7/5)

-

Output & Pressure: 10.5–70 MW; ≤2.5 MPa

-

Fuel: Natural gas or light oil

-

Thermal Efficiency: >96 % leveraging SZS water‑tube design

-

Advantages:

-

Ideal For: Large shopping malls, factories, district heating, stations, airports

-

Recommendation: ★★★★★ (4.9/5)

Gas/Oil‑Fired Integrated Hot‑Water Boiler

-

Output & Pressure: 0.7–14 MW; ≤1.25 MPa

-

Fuel: Natural gas or light oil

-

Advantages:

-

Skid‑mounted “all‑in‑one” unit—piping, feedtank and controls pre‑assembled

-

Reduces on‑site civil and piping work

-

Ideal For: Schools, small to mid‑size hotels, hospitals

-

Recommendation: ★★★★☆ (4.6)

Gas/Oil‑Fired Split Hot‑Water Boiler

-

Output & Pressure: 0.7–14 MW; ≤1.25 MPa

-

Fuel: Natural gas or light oil

-

Advantages:

-

Ideal For: Retrofit projects, modular campuses

-

Recommendation: ★★★★☆ (4.5)

-

Output & Pressure: 0.7–2.8 MW; -0.02MPa

-

Fuel: Natural gas

-

Advantages:

-

Ideal For: Retail stores, small office complexes

-

Recommendation: ★★★★★ (4.8)

T6 & T7 Vacuum Hot‑Water Boilers

-

Output & Pressure:

-

Fuel: Natural gas or light oil

-

Advantages:

-

Ideal For: Hospitals, laboratories, high‑rise buildings, high-end communities, central heating

-

Recommendation: ★★★★★ (4.9)

-

Output & Pressure: 0.1–2.8 MW; ≤1.0 MPa

-

Fuel: Electricity

-

Advantages:

-

Ideal For: Emission‑sensitive zones, green buildings

-

Recommendation: ★★★★☆ (4.2)

-

Thermal Efficiency: Up to 97 % (EN 303 certified)

-

Emissions: NOₓ ≤15 mg/m³ (EN 676 compliant)

-

Footprint: 1.8 m³ compact housing

-

Advantages:

-

Ideal For: High‑efficiency retrofits, LEED‑certified projects

-

Recommendation: ★★★★★ (4.7)

-

Output Range: Varies by model; typically 1–20 MW

-

Fuel: Coal or agricultural biomass

-

Advantages:

-

Ideal For: Rural or industrial sites with biomass availability

-

Recommendation: ★★★★☆ (4.1)

Recommendation Index Legend

-

4.8-5.0: Industry‑leading performance and efficiency

-

4.6-4.7: Excellent overall, minor trade‑offs

-

4.4-4.5: Strong choice for typical applications

-

4.3: Good niche solution

-

4.0-4.2: Suitable for limited or specialized scenarios

This lineup demonstrates FANGKUAI’s ability to address virtually any commercial heating requirement, from boutique 100 kW applications to 70 MW district‑scale systems, all backed by robust R&D, factory automation and global service support.

Contact us now and we will have professional technicians calculate the minimum and maximum heat load for you. We will design a solution for you to avoid overcapacity or undercapacity of the boiler. We will provide you with a satisfactory answer with the highest cost performance.