How to Choose a Steam Boiler for the Corrugated Packaging Industry?

date: 2024-12-23

Page preview:

The corrugated packaging industry relies heavily on steam for processes such as heating, moistening, and shaping paper. Therefore, selecting the right steam boiler is crucial for improving production efficiency, reducing operating costs, and achieving energy savings. Here are the key factors to consider when choosing a steam boiler for the corrugated packaging industry:

1. Boiler Capacity

Corrugated production lines require a stable and continuous steam supply. The boiler capacity must meet the demand of the production line. Depending on the scale of production, you can choose boilers with different evaporation capacities. Typically, boilers with an output of 10-50 tons per hour are recommended for large-scale corrugated paper production.

2. Fuel Type

Natural gas boilers are widely used in the corrugated packaging industry due to their clean and efficient nature. They can run on natural gas, LPG, or other clean fuels, which help reduce emissions and comply with environmental regulations. If your factory has a stable natural gas supply, gas-fired boilers are an energy-efficient solution.

3. Efficiency and Energy Savings

The energy consumption in corrugated production is significant, so the efficiency of the boiler directly impacts operational costs. High-efficiency boilers, especially condensing steam boilers, are ideal because they recover waste heat from flue gases to increase overall thermal efficiency, reducing fuel costs. For example, Fangkuai’s SZS series water tube steam boiler achieves thermal efficiencies between 92%-106%, significantly reducing fuel consumption.

4. Emission Standards

Environmental sustainability is a growing concern in the corrugated packaging industry. Therefore, the emissions from boilers, including nitrogen oxides (NOx) and carbon dioxide (CO2), should meet local environmental regulations. Low-NOx boilers, such as those with NOx emissions below 30mg/m³, help reduce environmental impact and avoid regulatory penalties.

5. Operational Stability and Safety

The steam boiler must operate continuously and reliably to avoid disruptions in the production process. Automation and safety features are essential considerations when selecting a boiler. Boilers with safety features like overpressure alarms, low water level protection, and over-temperature protection enhance operational safety. The SZS series steam boiler, for example, comes equipped with these protections to ensure safe and stable operation.

6. Intelligent Controls and Easy Maintenance

With the advancement of industrial automation, intelligent boilers are becoming more prevalent. Boilers equipped with smart monitoring and remote management systems can monitor operational status in real time, provide fault warnings, and reduce manual intervention. Additionally, choosing a boiler with easy maintenance features can lower long-term operating costs.

7. Plant Layout and Boiler Size

Boiler installation space is another factor to consider, especially if the plant has limited room. Opting for compact boilers with easy installation can reduce modification costs and installation time. Condensing steam boilers, for example, are smaller in size and easy to install, saving valuable floor space in the plant.

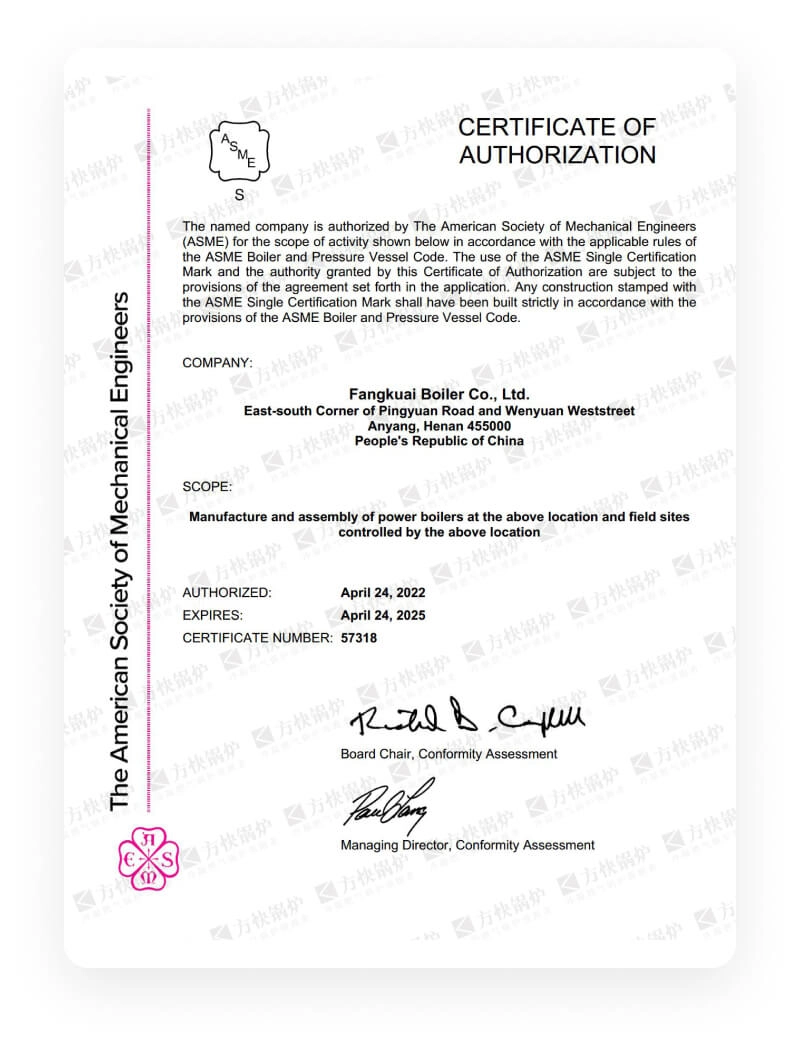

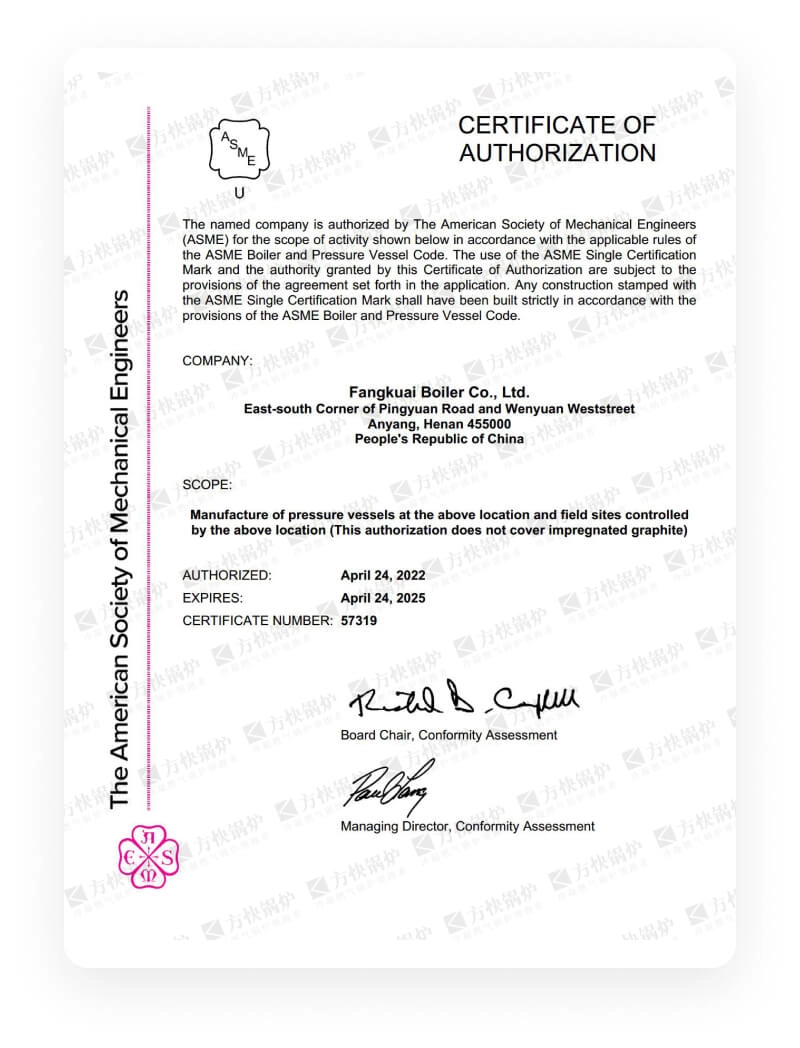

8. Industry Experience and Technical Support

It’s important to choose a boiler manufacturer with extensive industry experience and strong after-sales support. Fangkuai Boiler, as a Class-A boiler manufacturer, has extensive experience in providing steam solutions to the corrugated packaging industry. They offer free design consultation and technical support, ensuring the boiler system is tailored to the specific needs of your production line. Their technical team can also assist with fuel cost calculations and efficiency improvements, ensuring smooth and cost-effective production.

Conclusion

When selecting a steam boiler for the corrugated packaging industry, it is essential to focus on factors such as boiler capacity, fuel type, energy efficiency, environmental compliance, safety, and intelligent controls. Choosing a high-efficiency, environmentally friendly boiler like Fangkuai’s SZS series water tube steam boiler can help reduce costs, improve production efficiency, and meet stricter environmental regulations.