How Santa Keeps Industrial Boilers Running Heat and Steam During the Holidays

date: 2025-12-25

Page preview:

Christmas is finally here.

Lights are glowing, music is playing, and people everywhere are slowing down — just a little.

From my sleigh, I can see families gathering, shops buzzing, restaurants full of laughter.

And I can’t help but smile.

Christmas is about warmth.

Not just in our hearts — but in our buildings too.

Because while the world celebrates, heating and steam systems are still hard at work.

Christmas Joy, Real-World Demands

Let’s be honest — Christmas doesn’t pause reality.

Shopping centres still need comfortable indoor heating.

Bars and restaurants are busier than ever.

Factories and industrial facilities continue operating, even through the holidays.

For heating, that warmth comes from industrial hot water boilers.

For production and processing, it comes from high-temperature steam systems.

Different systems.

Different purposes.

But the same expectation: everything must keep running smoothly.

And as Santa, that’s something I care deeply about.

Fewer People On Site, No Room for Mistakes

Here’s the quiet challenge of the holiday season.

There are fewer operators on duty.

Response times are longer.

Yet responsibility doesn’t disappear just because it’s Christmas.

A heating failure in a shopping mall?

Unacceptable.

A steam interruption in an industrial process?

Costly and stressful — especially during the holidays.

That’s why holiday operation isn’t about working harder.

It’s about working smarter.

Why Smart Boiler Control Matters More at Christmas

Traditional boiler systems depend heavily on manual checks and on-site attention.

That approach feels fragile during holidays.

Modern systems don’t.

Industrial hot water boilers for heating, and steam boilers for process use, are increasingly equipped with PLC-based intelligent control systems.

These systems continuously monitor:

-

Temperature

-

Pressure

-

Water levels

-

Overall operating status

Built-in safety logic and automatic protection work quietly in the background — even while everyone else is enjoying Christmas dinner.

Checking the Boiler… Without Leaving Home

One of my favourite modern comforts?

Remote monitoring.

With intelligent PLC control, operators don’t need to rush back to site just to “check if everything is okay”.

Even from home, they can:

-

View real-time operating data

-

Receive alarms immediately

-

Confirm that heating and steam systems are running normally

That peace of mind matters — especially during the holidays.

Because Christmas should be about family, not emergency call-outs.

One Intelligent Boiler Control Approach, Many Applications

What truly makes me happy is seeing one control philosophy support so many scenarios:

Whether it’s heating or steam,

commercial buildings or industrial facilities,

intelligent control keeps everything steady and predictable.

And that’s exactly how it should be.

Automation: The Quiet Helper Behind a Happy Holiday

I’ve learned something over the years.

Holiday reliability doesn’t come from luck.

It comes from good design and intelligent automation.

PLC control systems don’t get distracted.

They don’t miss alarms.

And they certainly don’t take holidays.

They quietly do their job — so everyone else can enjoy theirs.

Warm Buildings, Steady Steam, and a Merry Christmas

Christmas is a time for warmth, comfort, and peace of mind.

Industrial hot water boilers keep buildings warm.

Steam boilers keep industries moving.

And intelligent PLC control keeps everything under watch — even when nobody is on site.

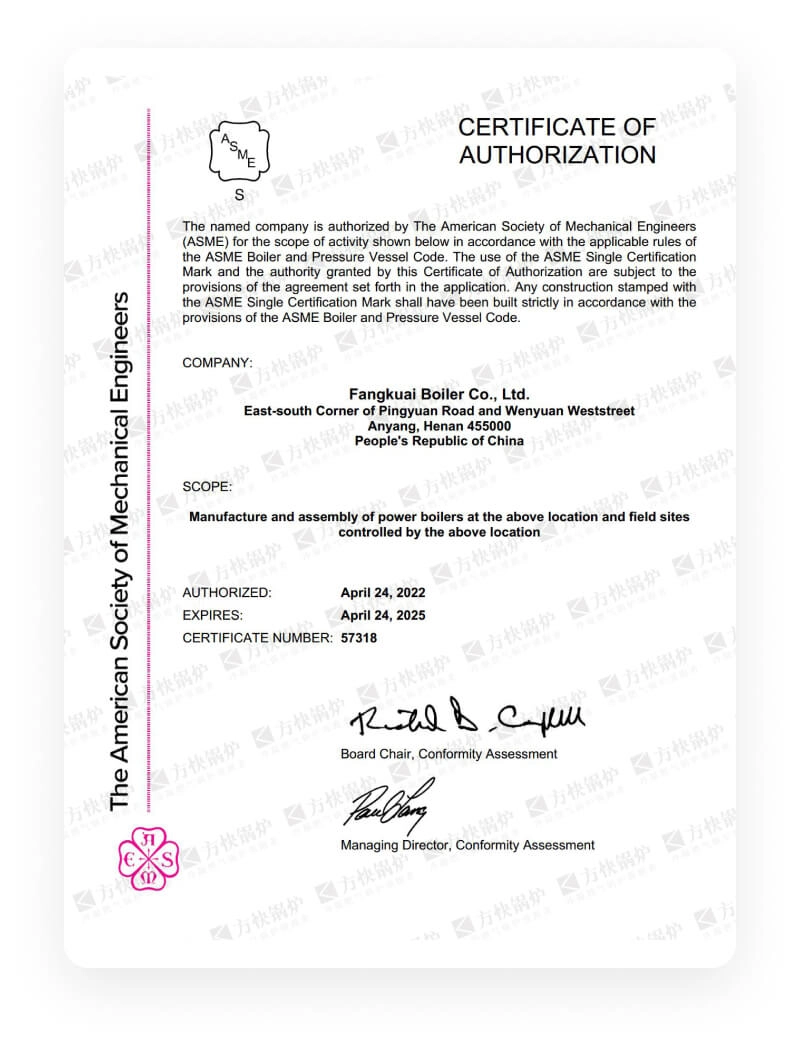

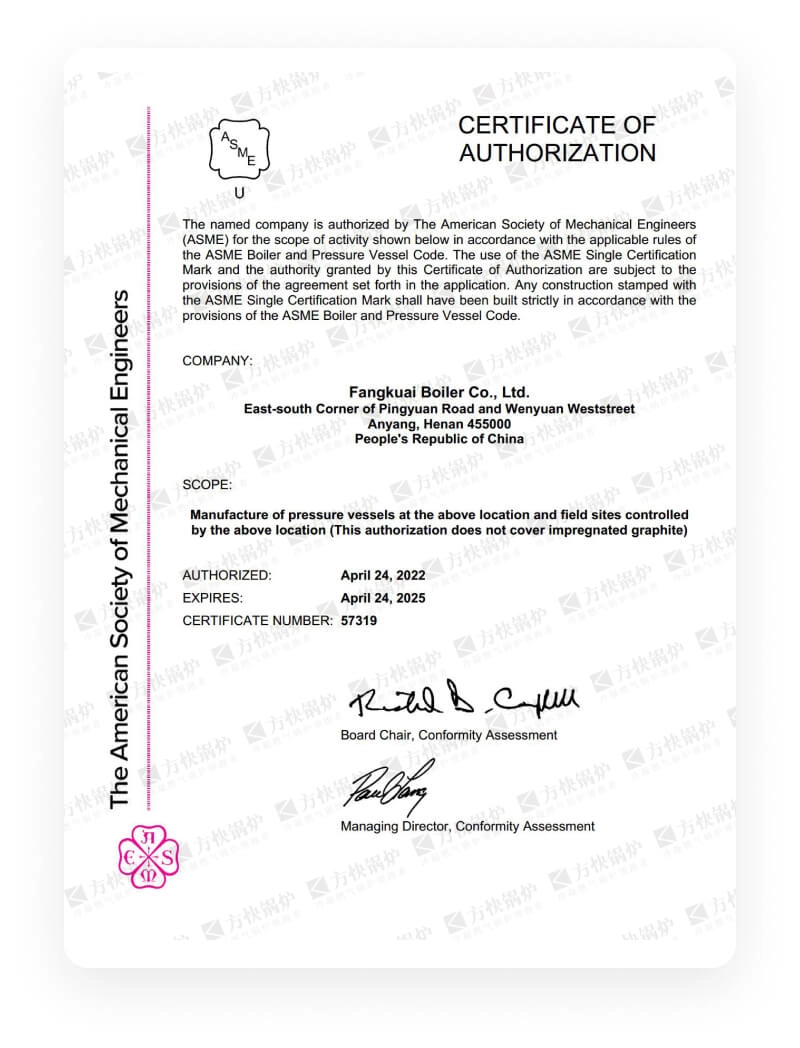

At FangKuai Boiler, that’s how we believe boilers should work:

reliable, well-controlled, and ready for real life — holidays included.

From me to you,

Merry Christmas, warm buildings, steady steam, and a joyful holiday season.