Water-tube boiler vs Fire-tube boiler | Boilers Guide

date: 2025-08-18

Page preview:

I cover how each type works, how to tell them apart (including what to look for in photos), their pros & cons, and why water-tube boilers generally give higher efficiency.

Introduction

There are two common industrial boiler families: fire-tube boilers (hot combustion gases run inside tubes surrounded by water) and water-tube boilers (water/steam runs inside tubes surrounded by hot gases). Each design has different strengths and typical applications — fire-tube for smaller, lower-pressure duties and water-tube for high-pressure, high-capacity steam.

Working Principle of Water Tube Boiler vs Fire Tube Boiler

Water-tube boiler — working principle

Water flows through many small diameter tubes. Combustion gases (from the furnace) pass around those tubes and transfer heat to the water inside. The heated water/steam collects in drums or headers; because the water is confined to tubes the boiler can be built for very high pressure and rapid steam generation.

Fire-tube boiler — working principle

Hot furnace gases travel through a bundle of tubes that run inside a large pressure vessel (shell) filled with water. Heat from the flue gases transfers through tube walls into the surrounding water; steam/hot water collects above the waterline in the shell. Fire-tube boilers are simple and robust for lower pressures and smaller steam outputs.

How to distinguish between fire tube boilers and water tube boilers

Practical tips:

- Visually inspect: if you see top/bottom steam drums and many parallel small tubes (water flows inside the tubes) it’s a water-tube boiler; if you see a large, thick horizontal cylindrical shell with the burner on the end (hot gases pass through tubes) it’s a fire-tube boiler.

- Check the nameplate or technical documentation to confirm the model and boiler type.

Advantages and Disadvantages of Water Tube Boilers and Fire Tube Boilers

Water-tube — pros

-

Handles much higher pressure and temperature (suitable for power-plant and large industrial steam).

-

Faster steam production / quicker start because of low water content and high heat transfer surface.

-

Better suited to very large steam flows and responsive load changes.

Water-tube — cons

-

More complex design and controls; requires stricter water chemistry and feedwater quality.

-

Usually higher initial engineering/installation complexity (though at very large capacities life-cycle cost can be favorable).

Fire-tube — pros

-

Simple, rugged, easier to operate and maintain; lower first cost for small installations.

-

Tolerant of poorer water quality (for moderate pressures) and forgiving in low-demand intermittent use.

Fire-tube — cons

-

Limited maximum pressure and steam generation rate; becomes impractical for large, high-pressure plants.

-

Slower to respond and generally heavier for the same steam output.

Why water-tube boilers are often more efficient (practical reasons)

When people say water-tube boilers are “more efficient” they usually mean they give better fuel-to-steam performance and operational efficiency in medium-to-large applications. Key reasons:

-

Lower water inventory → faster heat up and less standby loss. Less water mass means the boiler reaches operating temperature more quickly and wastes less fuel during start/stop or turndown.

-

Higher heat transfer area per unit volume. Water-tube designs use many small tubes and can create a larger effective heating surface and stronger convective heat transfer, speeding evaporation.

-

Better turndown and control at high pressures. Because of the tube geometry and drum arrangements, water-tube boilers can manage rapid load swings and keep combustion efficient across a wide range.

-

Designed for high pressures & superheating. Efficient power-generation cycles often require high pressure and superheated steam — conditions where water-tube designs excel.

(Keep in mind: for small building heating applications a modern condensing fire-tube boiler can be highly efficient; the “water-tube is more efficient” advantage is most relevant at higher capacities and pressures.)

How do I choose between a fire tube boiler and a water tube boiler?

-

Choose fire-tube for small to medium steam needs, simple maintenance, lower capital cost, and tolerant water conditions.

-

Choose water-tube for high pressure, large capacity, quick startup, and when tight control/fast response is needed. Consider water treatment and operator skill requirements for water-tube plants.

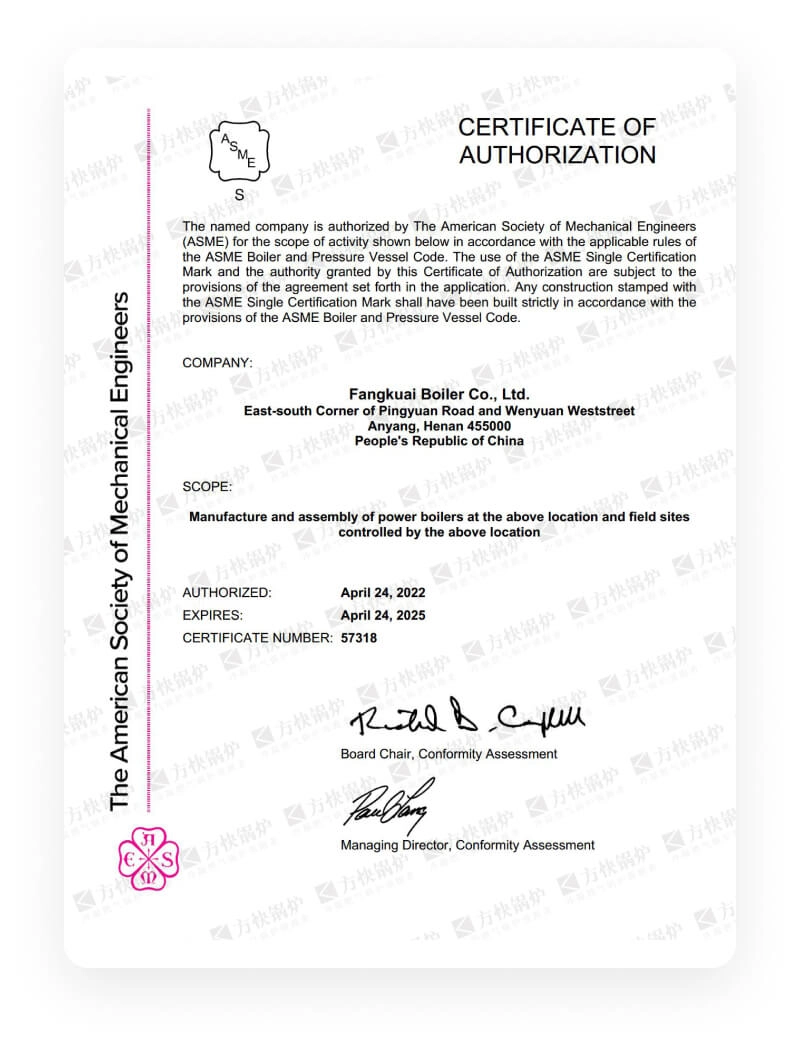

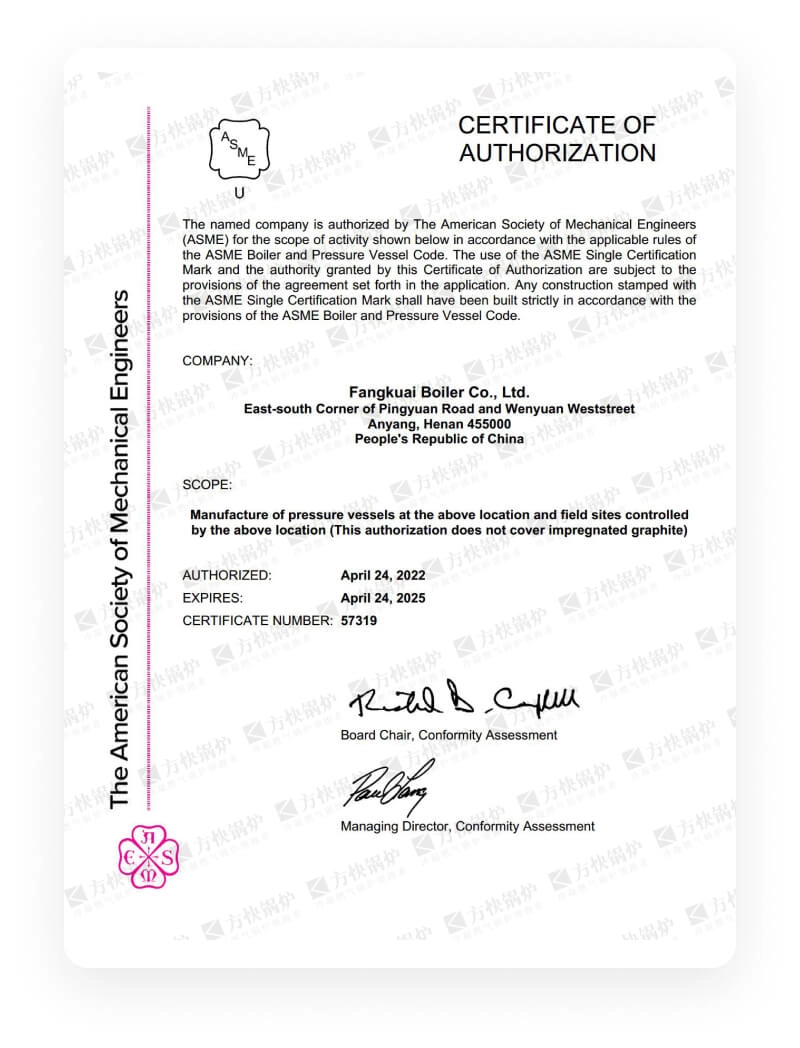

If you're having trouble selecting a model, please contact us. We've specialized in industrial boiler production for 30 years. We provide customized industrial boiler solutions for hundreds of factories and businesses each year. Our clients include internationally renowned companies like Sinopec, Yili, Xiaopeng Motors, and Zijin Mining.