How to Maximize Savings with Gas-Fired Steam Boilers?

date: 2025-12-13

Page preview:

For any facility relying on steam for process heat, sterilization, or power generation, the gas-fired steam boiler is a critical yet often costly asset. Its total lifetime financial impact extends far beyond the initial purchase, weaving through installation, daily operation, and long-term maintenance.

Achieving genuine cost savings requires a holistic strategy that scrutinizes every phase of the boiler's lifecycle: procurement, installation, and maintenance. By intelligently managing factors like energy expenses, boiler efficiency, and operational management, significant reductions in overall gas steam boiler costs are not just possible but predictable.

1. Strategic Procurement: Navigating Initial Gas Steam Boiler Prices

The journey to savings begins at the purchase decision. The upfront gas steam boiler price is a significant component, but it should be evaluated as an investment in future efficiency, not merely a capital expense.

Focus on Efficiency Ratings: A higher-priced boiler with superior thermal efficiency (often indicated by annual fuel utilization efficiency or AFUE) may have a greater initial outlay but will consistently consume less fuel. Over a 15-20 year lifespan, the savings on energy expenses can dwarf the initial price difference. Look for models with advanced features like condensing technology, which recovers latent heat from flue gases, dramatically boosting efficiency.

Right-Sizing is Critical: Purchasing an oversized boiler leads to cyclic, inefficient operation (short cycling), increasing wear and fuel use. An undersized unit will struggle to meet demand. A professional load calculation ensures you pay for a gas-fired steam boiler with the optimal capacity, balancing performance and price.

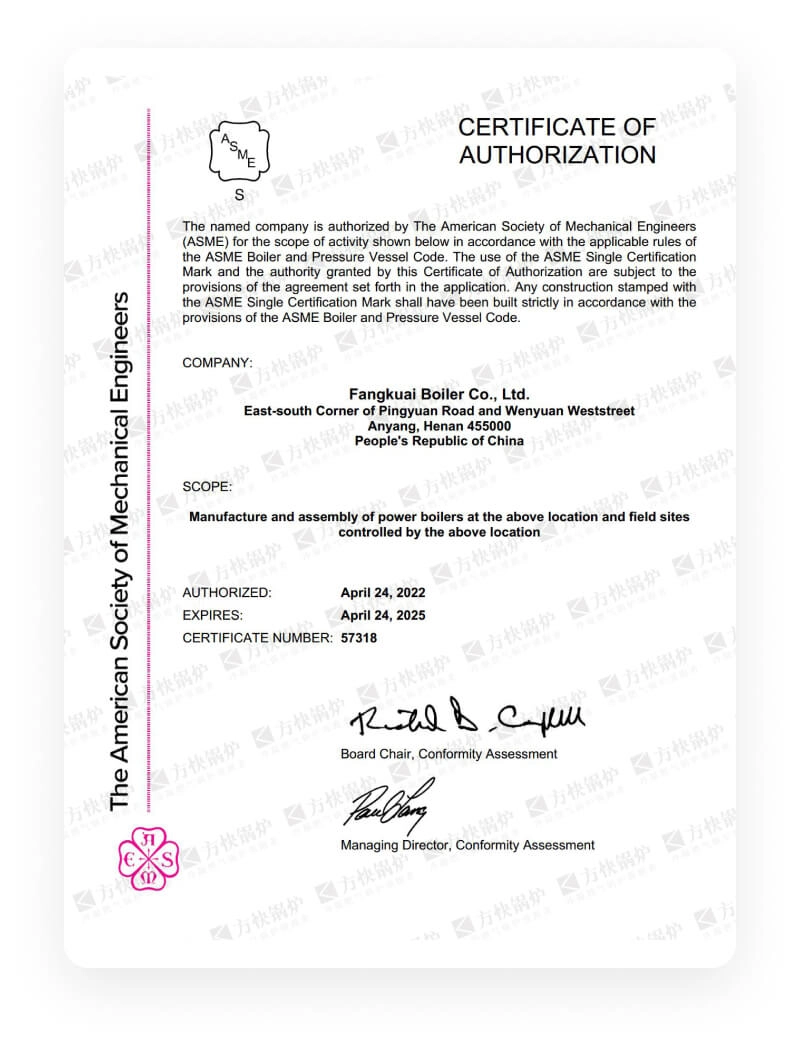

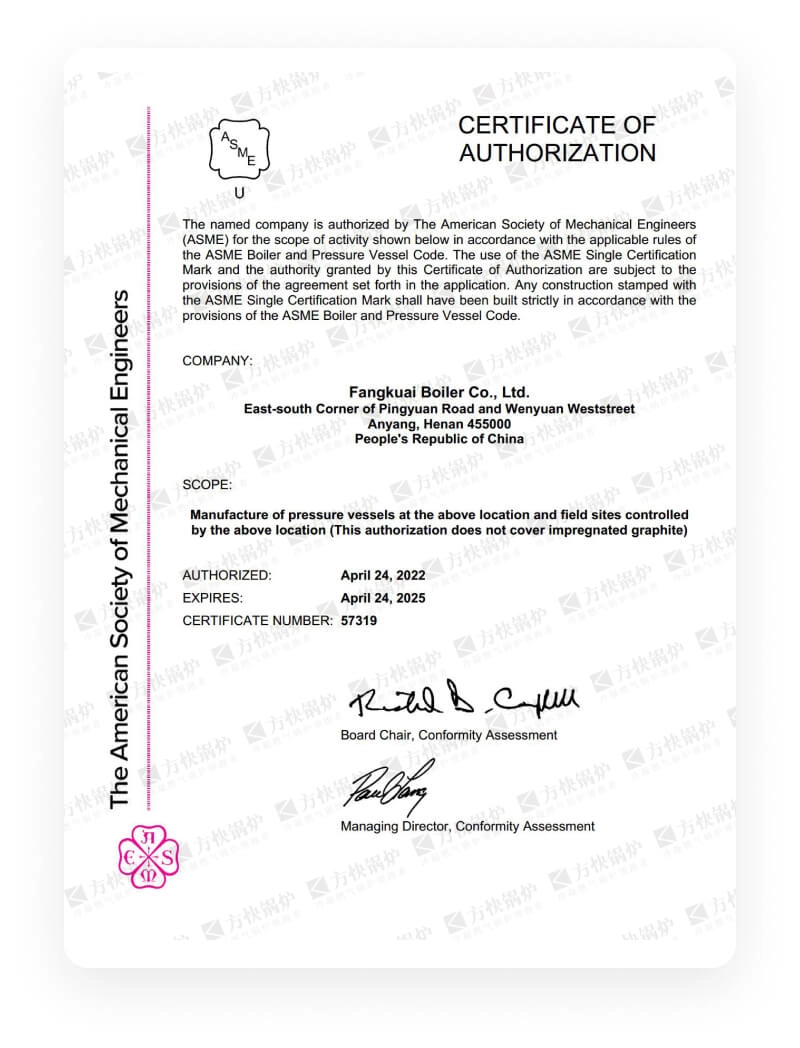

Quality and Longevity: Cheaper, low-quality components often lead to higher repair costs and shorter service life. Investing in a robust, well-constructed boiler from a reputable manufacturer may have a higher price tag but typically results in lower total costs through improved reliability and durability.

2. Precision Installation: Laying the Foundation for Low Gas Steam Boiler Costs

Even the most efficient boiler can be crippled by a poor installation. Professional installation is non-negotiable for minimizing long-term gas steam boiler expenses.

System Integration and Balance: A proper installation ensures the boiler is perfectly integrated with ancillary systems—pumps, piping, economizers, and feedwater systems. Correctly sized and installed piping with adequate insulation minimizes heat loss. Properly balanced distribution ensures steam is delivered efficiently, directly reducing fuel consumption.

Optimizing for Peak Efficiency: Key installation steps directly impact boiler efficiency. This includes proper burner setup for optimal air-fuel ratio, correct calibration of controls, and installation of essential instrumentation for monitoring. A well-installed boiler starts its life operating at its designed peak performance, which is the most effective way to control energy expenses from day one.

Future-Proofing with Controls: Integrating advanced control systems during installation is a major saving strategy. Programmable thermostats, outdoor reset controls, and building management system (BMS) interfaces allow for precise operational management, modulating boiler output based on real demand and preventing wasteful operation.

3. Proactive Maintenance: The Key to Controlling Long-Term Gas Steam Boiler Expenses

Neglecting maintenance is the fastest way to inflate operating costs. A proactive, planned maintenance regimen is the most powerful tool for sustaining savings.

Preserving Boiler Efficiency: The core goal of maintenance is to keep the boiler running at its original, as-installed efficiency. Regular tasks like soot blowing, cleaning heat exchanger surfaces, and tuning the burner prevent gradual efficiency decay. Even a small percentage drop in efficiency can lead to a substantial, year-long increase in gas steam boiler fuel costs.

Preventing Costly Failures: Scheduled inspections identify small issues—like a leaking seal, pump vibration, or minor corrosion—before they escalate into catastrophic, expensive failures. The cost of a planned replacement part and labor is invariably lower than the expense of an emergency repair, production downtime, and potential collateral damage.

Strategic Operational Management: Effective maintenance goes hand-in-hand with daily operational management. This includes routine monitoring of stack temperature, feedwater quality, and steam pressure. Proper water treatment is especially critical; scale and corrosion inside the boiler are immense insulators that drastically reduce heat transfer, spiking fuel use. Training staff on efficient daily procedures, such as optimizing boiler sequencing in multi-boiler plants, compounds these savings.

FAQ: Common Questions on Gas Steam Boiler Costs and Savings

Q1: Is a high-efficiency boiler worth the higher initial gas steam boiler price?

A: Almost always, yes. The premium paid for a high-efficiency model is an investment with a clear return. The savings on monthly energy expenses from reduced fuel consumption typically result in a payback period of just a few years. Over the boiler's full lifespan, the total gas steam boiler cost of ownership is usually far lower.

Q2: How can I quickly estimate if my current boiler is inefficient?

A: Monitor your fuel bills for unexplained increases and check the boiler's stack (flue) temperature. A consistently high stack temperature often indicates heat is being wasted up the chimney instead of being used to make steam, pointing to declining boiler efficiency. Regular efficiency testing by a professional is the most accurate method.

Q3: What is the single most important maintenance task to control gas steam boiler expenses?

A: While a comprehensive program is essential, proper water treatment is arguably the most critical. Scale buildup of just 1/8 inch on heat exchange surfaces can increase fuel consumption by up to 10-15%. Preventing scale and corrosion protects efficiency and the boiler's structural integrity.

Q4: How does operational management affect costs on a day-to-day basis?

A: Daily practices have a huge impact. Simple actions like ensuring steam traps are functioning, eliminating steam leaks, and adjusting boiler pressure to the minimum required level can lead to immediate savings. Properly sequencing multiple boilers to match load demand is another key operational management strategy.

Q5: Should I repair or replace my old boiler?

A: Consider replacement if your boiler is over 20 years old, requires frequent and costly repairs, operates at significantly low efficiency, or can no longer meet demand efficiently. A cost-benefit analysis comparing annual repair expenses and fuel costs against the investment in a new, efficient unit will provide the clearest answer.

Conclusion

True economy with a gas-fired steam boiler is achieved not by minimizing any single expense, but by optimizing the entire system lifecycle. It requires viewing the higher initial gas steam boiler price of a high-efficiency model as a strategic down payment on future fuel savings.

It demands an investment in expert installation to unlock that designed efficiency. Finally, it is sustained through a disciplined, proactive maintenance program that protects that efficiency and prevents debilitating repair expenses.

By systematically addressing procurement, installation, and maintenance with a focus on energy expenses, boiler efficiency, and operational management, businesses can transform their gas steam boiler from a necessary cost center into a model of energy-efficient and cost-effective operation. The path to lower gas steam boiler costs is a continuous cycle of smart investment and vigilant care.