FangKuai Boiler Supplies 200 TPH Energy System for BYD’s European Plant

date: 2026-02-05

Page preview:

FangKuai Boiler has recently signed a boiler equipment supply contract for BYD’s first new energy passenger vehicle manufacturing base in Europe, marking an important step forward in FangKuai’s expansion into the European high-end industrial boiler market.

As a global leader in new energy vehicles, BYD applies strict technical, safety, and efficiency standards to its overseas manufacturing projects. After comprehensive evaluation, FangKuai Boiler was selected as the exclusive supplier of industrial boiler systems, based on its proven engineering capability, energy efficiency performance, and full compliance with European regulations.

200 TPH Modular Water-Tube Boiler Solution

For this project, FangKuai designed and delivered a modular water-tube boiler system with a total capacity of 200 tons of steam per hour. The system is engineered to support two core energy-intensive processes within the manufacturing facility while ensuring high reliability and operational flexibility.

-

Factory Heating and Environmental Control

The modular water-tube boiler system provides stable and responsive heat supply for large-scale production buildings. By combining multiple boiler modules under centralized control, the system maintains precise temperature and humidity conditions throughout the year, supporting consistent production quality in modern automotive manufacturing environments.

-

Energy Supply for Automotive Painting Lines

Automotive painting processes impose the highest requirements on steam stability, response speed, and operational reliability. FangKuai supplied a specialized industrial boiler configuration optimized for painting line operation, ensuring continuous and uniform energy delivery to meet strict European automotive coating standards.

Modular Design for Efficiency and Reliability

The modular boiler architecture allows individual water-tube boiler units to operate independently or in coordinated sequences, adapting to real-time load demand. This design improves overall system efficiency, enhances redundancy, and simplifies maintenance, making it particularly suitable for large-scale industrial users with fluctuating energy requirements.

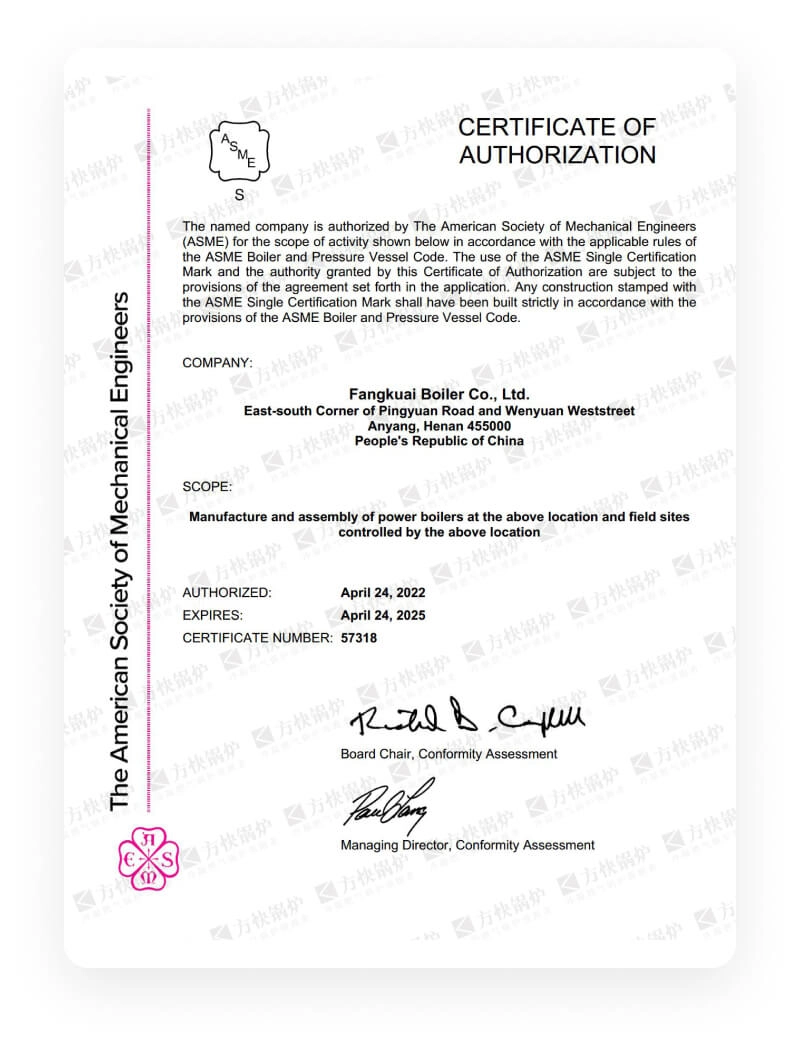

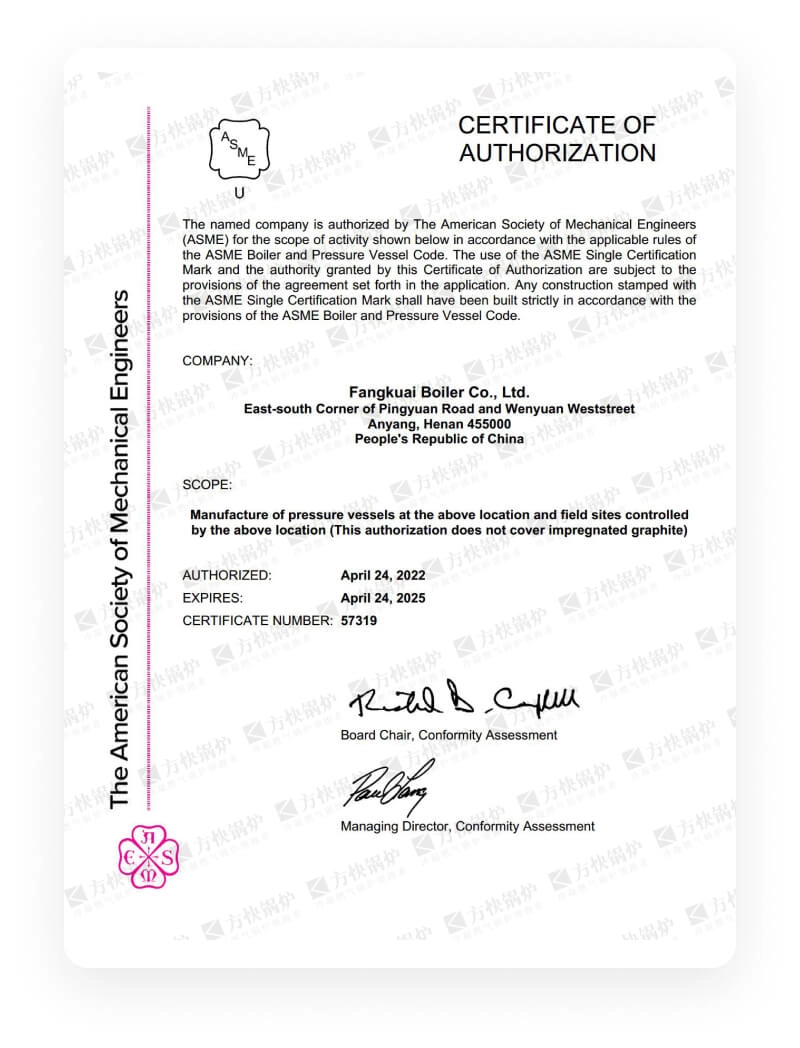

Full CE Compliance for the European Market

All boiler equipment supplied for the project is CE certified, confirming compliance with EU directives on safety, pressure equipment, and environmental performance. The certification reflects FangKuai’s comprehensive capabilities across design, manufacturing, testing, and quality management, ensuring smooth integration into European industrial facilities.

Strengthening FangKuai’s Global Strategy

This project represents a concrete milestone in FangKuai’s global development strategy—leveraging certified qualifications and core boiler technologies to serve high-standard international manufacturing projects.

By delivering modular, efficient, and compliant water-tube boiler systems, FangKuai continues to earn the trust of leading global manufacturers and actively participate in advanced international supply chains. The cooperation with BYD further demonstrates FangKuai’s ability to support the global expansion of Chinese manufacturing while contributing practical solutions toward carbon reduction and sustainable industrial development.