FangKuai Boiler Secures 162nd Patent with Innovative Heat‑Exchange Element

date: 2025-07-10

Page preview:

June 17, 2025, Changsha, China

FangKuai Boiler Company today announced that its independently developed patent, “Multi‑Stage Internal Fin High‑Efficiency Heat‑Exchange Element,” has been officially approved and granted by the China National Intellectual Property Administration. This latest authorization brings the company’s total to 162 national patents, further cementing its position at the forefront of industrial thermal‑energy technology.

Revolutionary Design Delivers Unmatched Heat Transfer

Confronting the longstanding challenge of improving heat‑exchange efficiency at high temperature and pressure, FangKuai’s patented element features:

-

3D Internal Fins: Dramatically increase the effective heat‑transfer surface area and maintain prolonged fluid contact.

-

Spiral Turbulence Channels: Generate continuous turbulence to dynamically boost thermal performance.

-

Modular Construction: Enables flexible assembly to suit diverse operating conditions while ensuring both efficiency and reliability.

This new finned‑tube design not only prevents the common problems of fin loosening and “cold spots,” but its streamlined shape also boosts heat transfer and long‑term reliability. That means you get better performance in boilers, chemical reactors, waste‑heat recovery units, and other demanding systems—translating directly into lower energy costs and smoother operations.

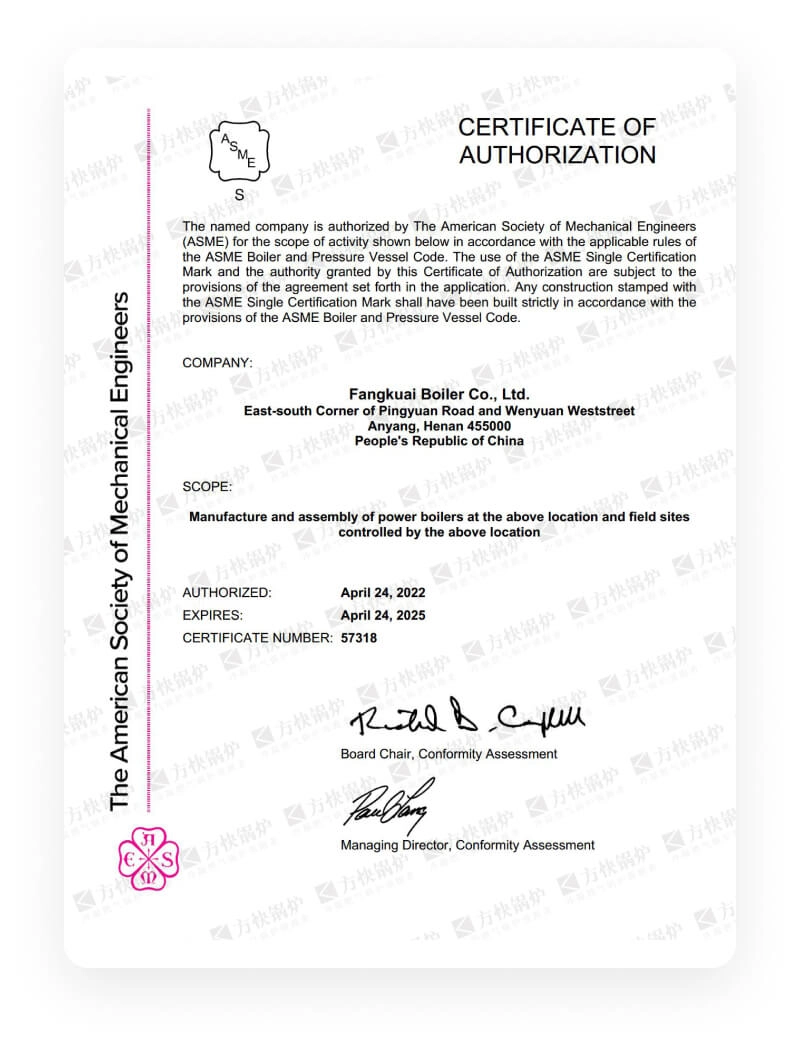

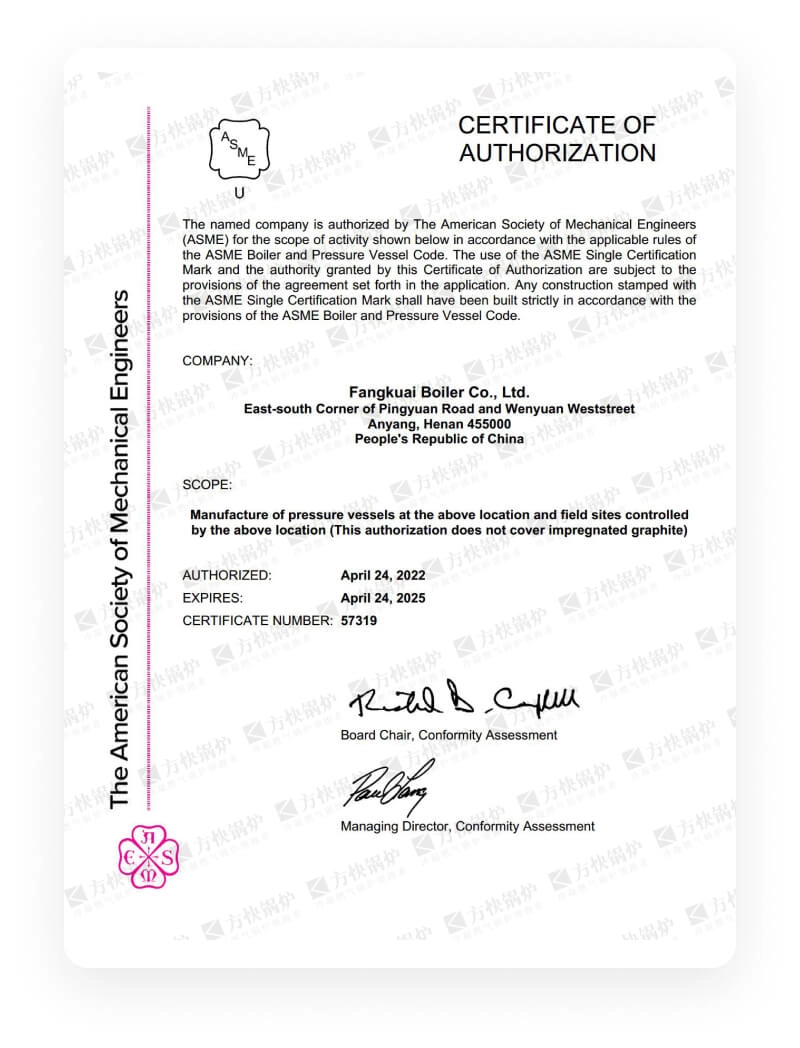

Patents and Standards: Two Pillars of Our Strategy

With 162 national patents (13 of them inventions) and a hand in writing eight key industry standards, we’ve built a feedback loop between cutting‑edge research, formal rule‑making, and real‑world products. This approach keeps us—and the thermal‑energy field as a whole—moving forward.

What’s Next: Putting Innovation to Work

“This patent is another proof point of our commitment to ever‑more efficient and greener heat solutions,” said Chairman Jianhua Li. “We’ll keep pouring resources into R&D—particularly in smart and digital energy technologies—to help our customers squeeze more value from every megajoule of heat.”

About FangKuai Boiler

Founded in 2005, FangKuai Boiler is a leading provider of comprehensive industrial thermal‑energy solutions. Its product portfolio includes oil‑ and gas‑fired boilers, steam generators, waste‑heat recovery units, and advanced control systems. Committed to “technology‑driven, quality‑first” principles, FangKuai serves customers worldwide with high‑efficiency, reliable, and eco‑friendly thermal‑energy products and services.