Gas Boiler General Overview - Boiler Manufacturers

date: 2024-10-26

Page preview:

What Is a Gas Boiler?

Gas boilers heat water or generate steam by burning natural gas, propane, or other gaseous fuels. You’ll find them in homes, businesses, and factories alike—valued for their clean operation, high efficiency, and lower emissions compared to coal- or oil-fired systems.

How They Work

-

Fuel supply: Gas arrives at the boiler through a pipeline.

-

Combustion: Inside the burner, gas and air mix and ignite, creating hot flue gases.

-

Heat transfer: Those gases flow through a heat exchanger, warming the water (or creating steam).

-

Distribution: The heated water or steam travels through pipes to radiators, underfloor heating, or process equipment.

Burner Types & Combustion Styles

-

Premixed burners combine gas and air before ignition, boosting efficiency and cutting emissions.

-

Staged burners introduce fuel and air in steps, ideal for large boilers where precise control matters.

-

Direct-fired burners spray gas into the chamber, a compact solution for smaller residential boilers.

Combustion can be natural-draft (relying on buoyancy of hot gases) or forced-draft (using fans to push air in), with forced drafts generally offering higher output and tighter control.

Maximizing Heat Transfer

Boiler efficiency hinges on how well heat moves from flue gases to water. Two common exchanger designs are:

-

Fire-tube: Hot gases travel through tubes surrounded by water—best for small to medium units.

-

Water-tube: Water runs inside tubes heated by flue gases—suited to high-capacity, industrial applications.

Getting More from Waste Heat

Condensate recovery and heat-recovery units capture leftover warmth in exhaust gases to preheat incoming water. That can boost efficiency by 10–20%, cutting fuel bills and easing the load on the boiler—so it lasts longer with fewer repairs.

Flue-Gas Recirculation (FGR)

By redirecting some exhaust back into the burner, FGR lowers peak combustion temperatures, reducing pollutant formation while squeezing out extra thermal efficiency. It’s a smart way to meet tight environmental rules and trim operating costs.

Fighting Corrosion

High heat and moisture demand rugged materials. Common choices include:

Why Certifications Matter

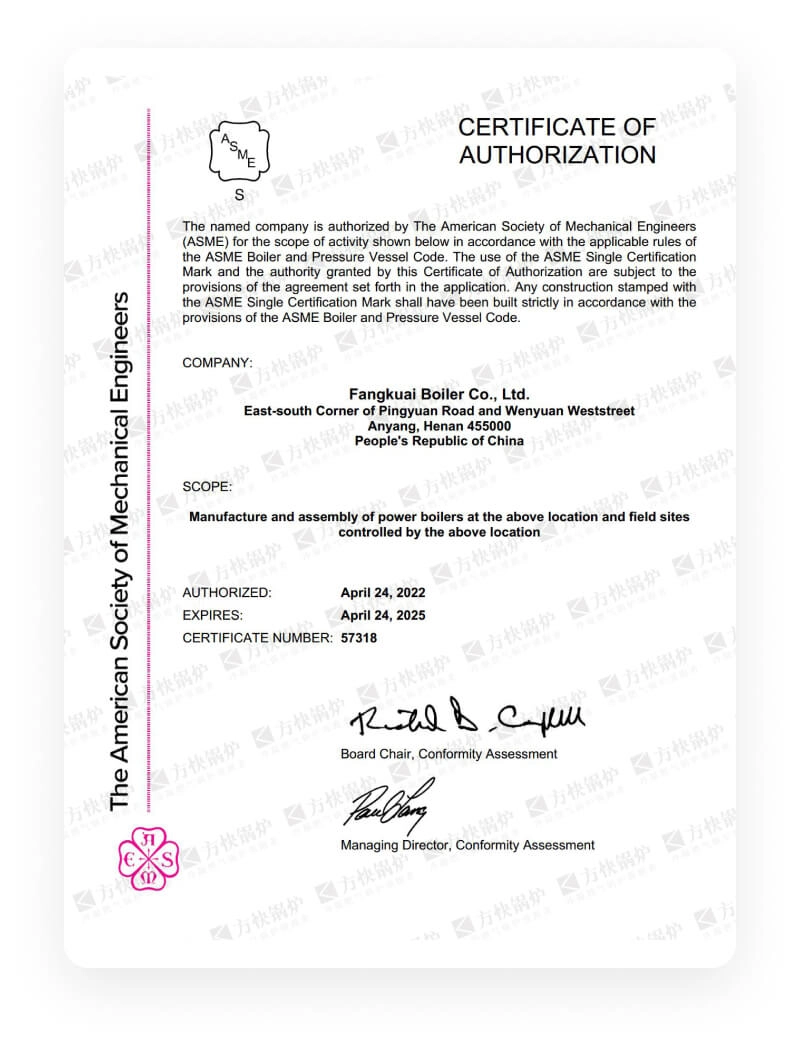

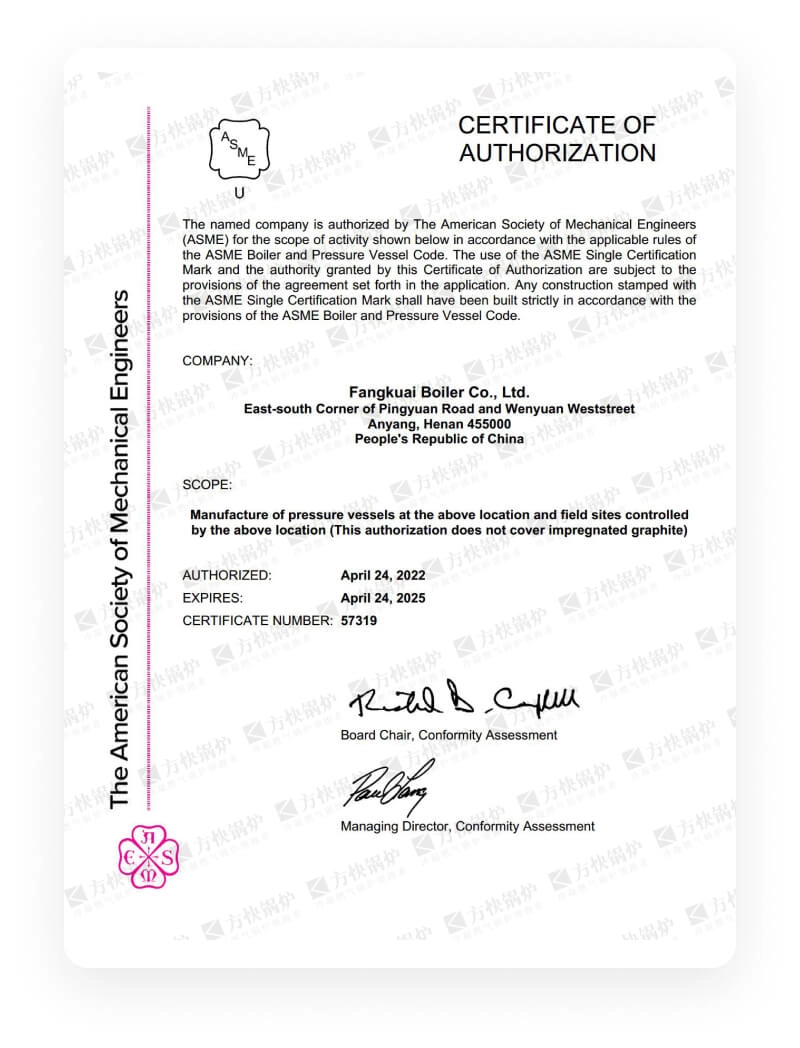

International marks prove a boiler meets safety, quality, and environmental standards:

-

ISO 9001: Guarantees consistent manufacturing processes.

-

CE marking: Required for Europe, attests to EU safety and emissions rules.

-

UL listing: Confirms compliance with North American safety norms.

What You’ll Pay

-

Residential units: $2,500–$7,500, depending on size and efficiency.

-

Industrial systems: Often start above $50,000, varying with capacity and custom features.

Is It Worth the Cost?

Natural gas prices tend to be steadier and lower than oil or electricity, making gas boilers a solid long-term investment. With fewer moving parts than alternative systems, routine upkeep is simpler and less expensive.

Maintenance & Safety

Keep your boiler reliable and safe by:

-

Cleaning and inspecting burners

-

Checking heat exchangers for scale or soot buildup

-

Testing safety valves, pressure gauges, and leak detectors

-

Ensuring automatic shutoffs are operational

Install a gas-leak alarm and overheat cut-offs to catch issues before they become emergencies.

Environmental Impact

Compared to coal or oil, gas burns cleaner—mostly water vapor and CO₂, with far less soot and nitrogen oxides. While CO₂ is still a greenhouse gas, modern gas boilers help businesses and homeowners shrink their carbon footprints and meet climate goals.

In summary, gas boilers blend efficiency, reliability, and relatively low emissions, making them a go-to heating solution across sectors. By choosing the right burner, adding recovery systems, and keeping up with maintenance and certifications, you can balance performance, cost, and environmental responsibility—and look forward to even better designs on the horizon.